Extend the life of your electric motors – 5 factors that matter

2025-07-07

What affects motor lifespan?

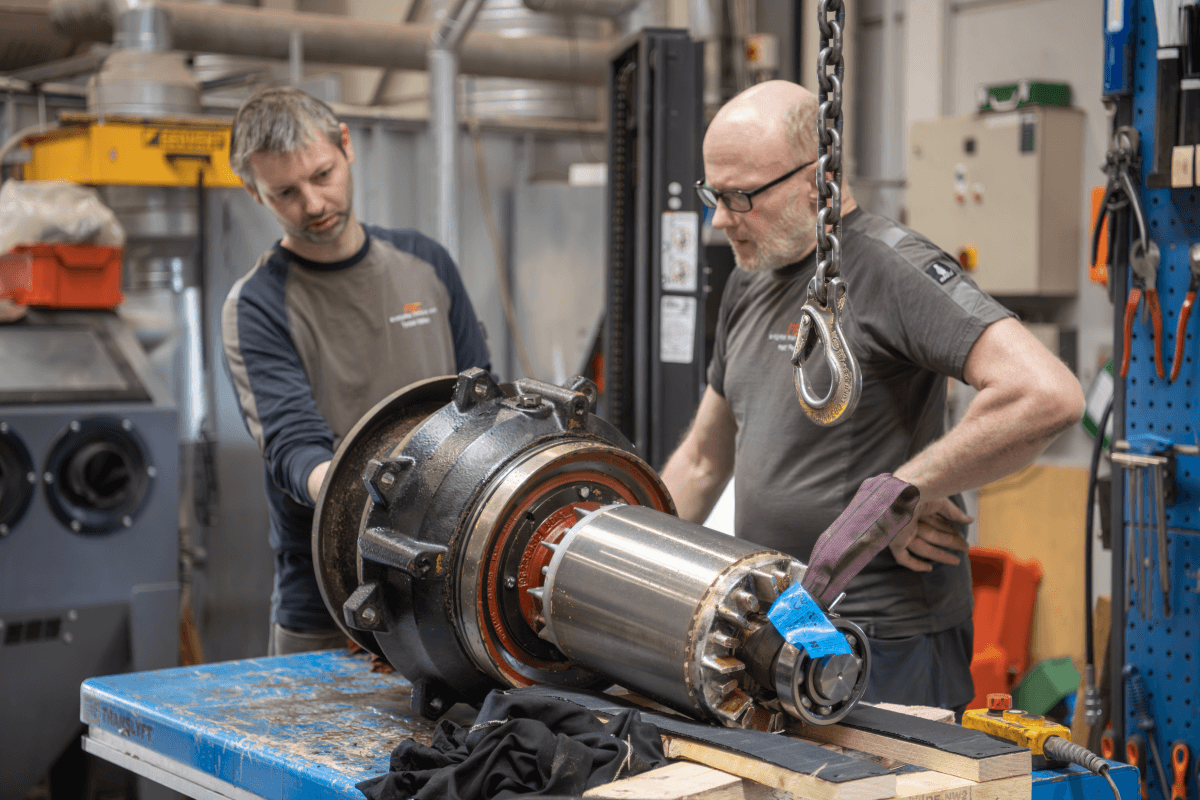

1. Misalignment

Even slight misalignment between motor and load can lead to increased vibration, heat and premature bearing failure. Laser alignment is a simple but essential service that ensures smooth operation and reduces stress across the system.

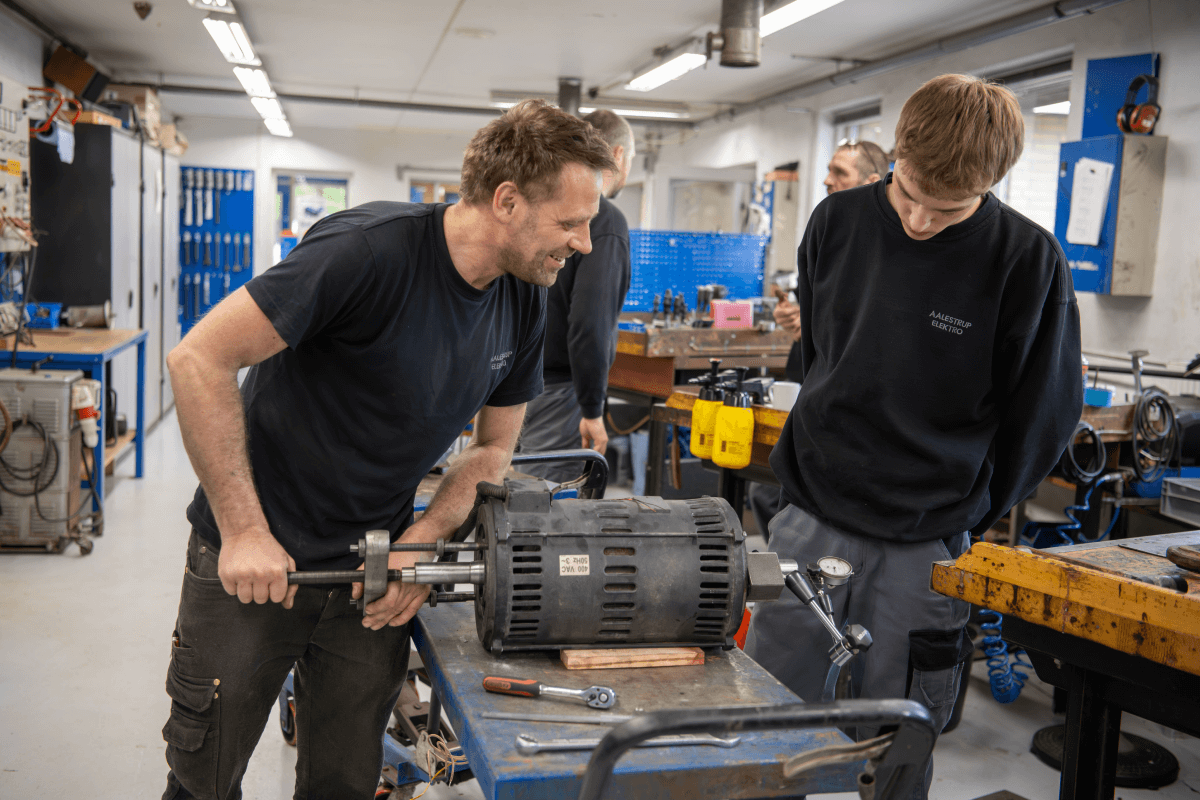

2. Imbalance and vibrations

Unbalanced rotors, worn parts or incorrect mounting can all cause vibration issues. These not only damage the motor itself but can also affect connected components. Through regular vibration measurements and balancing, we detect problems early and fix them fast.

3. Poor lubrication

Insufficient or excessive lubrication is one of the most common reasons for motor failure. It can lead to increased friction, overheating, and premature bearing wear – often long before the issue is visible. That’s why consistent lubrication checks and correct grease application are essential for long-term motor health.

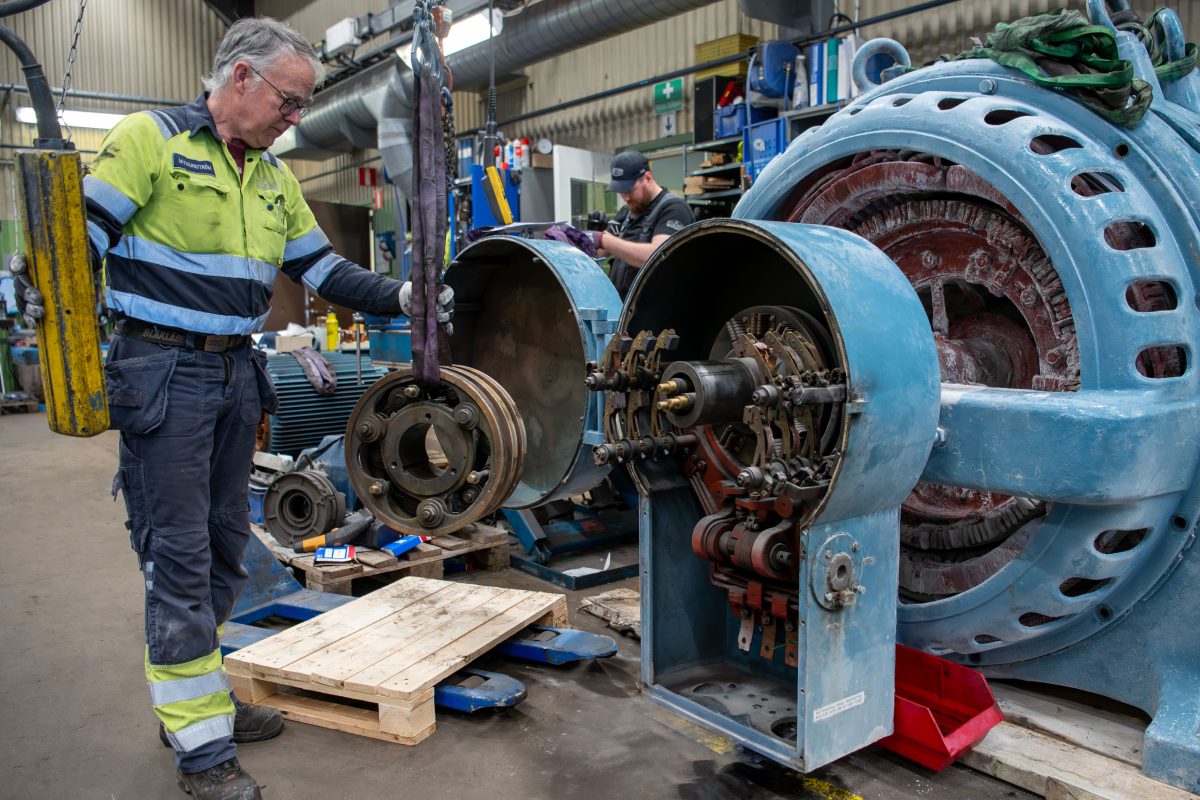

4. Overheating

Motors running above their temperature limits face shortened insulation life and increased failure risk. Overheating may result from blocked ventilation, overloading or environmental factors. Regular cleaning and system checks help prevent overheating and protect the motor’s insulation and internal components.

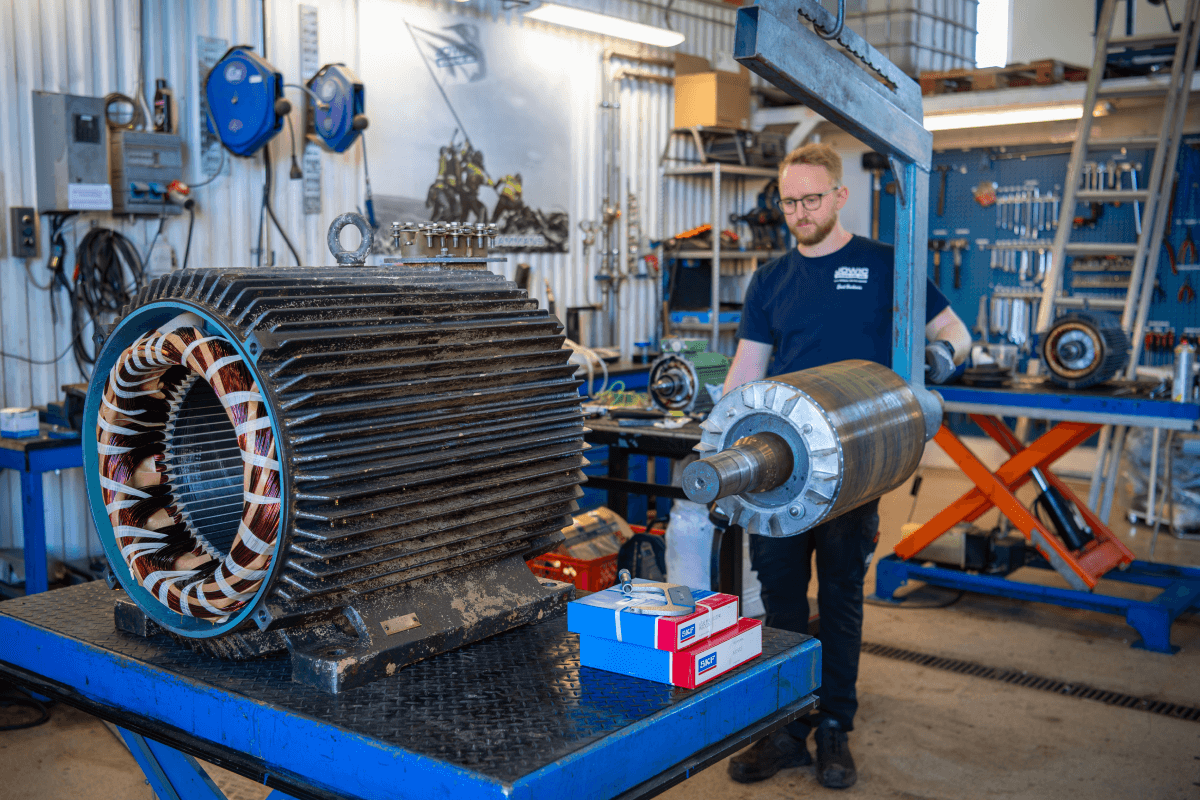

5. Contamination

Dust, moisture and chemical exposure can wear down components quickly – especially in tough environments. That’s why we provide custom sealing solutions, protective coatings and thorough cleaning during service.

Better maintenance means fewer breakdowns

From field diagnostics to full-scale reconditioning, we help industrial clients protect their motors – and their productivity. Our approach is proactive, precise and always aligned with your operating conditions.

More news

Midtjydsk Elektro strengthens lifting expertise through Dalmec

To sharpen their expertise in intelligent lifting systems, Midtjydsk Kran & Elektro recently visited Dalmec for in-depth training – reinforcing their ability to deliver safe and tailored lifting solutions.

Certification strengthens trust in Nordic Drives Group Söderhamn

Newly renewed ELR certifications reinforce Nordic Drives Group Söderhamn’s commitment to quality, safety, and industry-leading repair standards.

Common signs of pump failure and how to prevent them

Krylbo Elektra shares key warning signs of pump failure – and how proactive service can help avoid downtime and costly repairs.