Jowic Elteknik expands with a specialized workshop for frequency converter repairs

2024-10-24

What is a frequency converter and why is it important?

Frequency converters are crucial components in many industrial processes. These units allow for the control, regulation, and monitoring of electric motors. By adjusting the motor's speed and power output to specific requirements, rather than running it at full capacity continuously, frequency converters enable significant energy savings.

Given the central role electric motors play in industry – accounting for a substantial portion of energy consumption – the use of frequency converters can greatly enhance energy efficiency and reduce carbon emissions. At Jowic Elteknik, we continuously work on upgrading, configuring, and repairing these units to ensure they operate optimally and minimize energy consumption.

Why a specialized area for repairs?

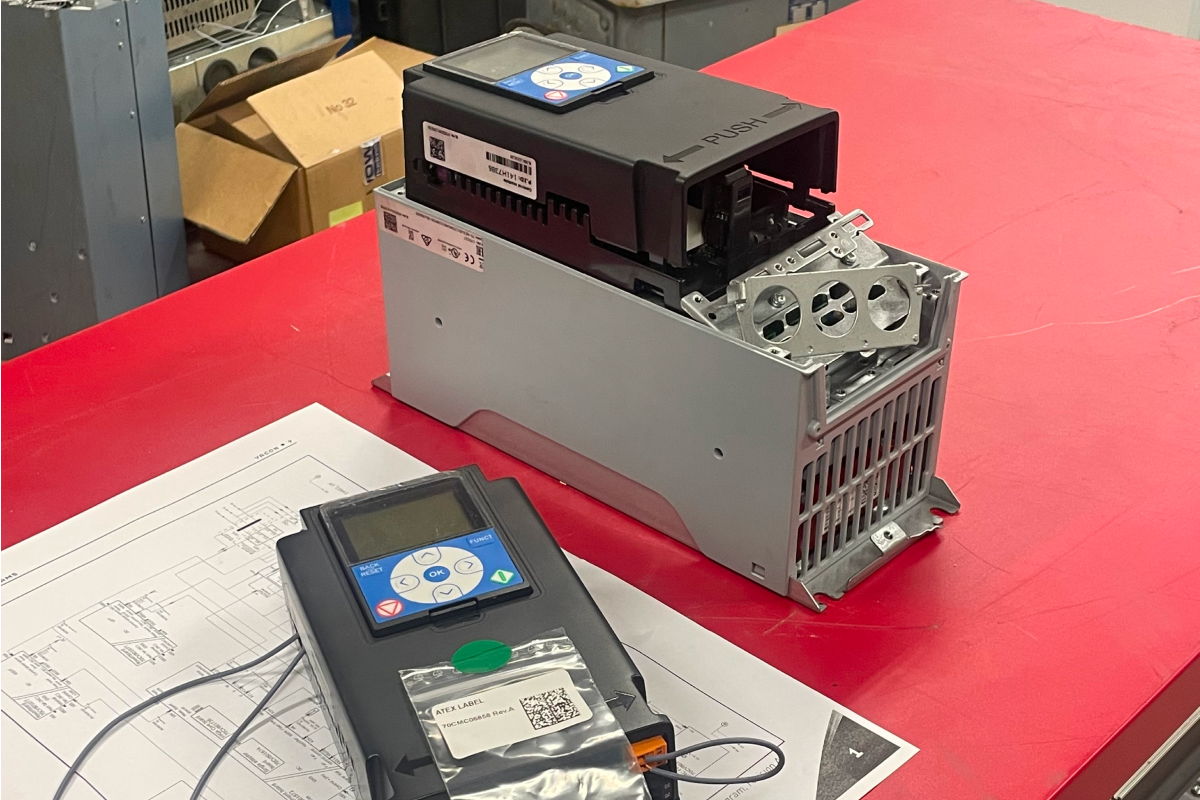

The decision to create a separate, dedicated section in the workshop for frequency converter repairs stems from the need to improve workflows and meet the increasing demands that come with being a service and warranty partner for Danfoss. Frequency converters are sensitive electrical equipment that require specific working conditions and a high degree of precision and safety during servicing.

– With this new division, we can work faster and more efficiently, benefiting our customers through shorter lead times and improved availability, explains Staffan from Jowic Elteknik.

The new area, called Drives Studio, was completed at the turn of the year and is equipped to handle both smaller units and larger converters up to 590A.

– We have recently strengthened our inventory to include larger units, which allows us to meet customer needs faster, thanks to shorter delivery times and improved accessibility, Staffan continues.

Benefits for our customers

Specializing part of the workshop exclusively for frequency converters offers numerous advantages. It has allowed the team to streamline internal processes, resulting in faster handling of incoming units and reduced customer waiting times. Additionally, the new area provides greater capacity to manage more tasks simultaneously, increasing flexibility and access to resources.

The expanded stock of frequency converters enables immediate access to spare parts and units when needed. For customers, this translates into shorter downtimes and better availability of critical components.

Future growth and development

Everyone at Jowic Elteknik has welcomed the new workshop area with enthusiasm. Looking ahead, there is great potential to continue growing and developing operations.

– Although we currently do not have any specific plans for further specializations, we are always looking ahead and striving to be faster and smarter, Staffan adds.

More news

We welcome Ceilog AB and Michael Östman to EMI AB and Nordic Drives Group

Ceilog AB and founder Michael Östman join EMI and Nordic Drives Group. Ceilog will be incorporated into EMI Kramfors and continue to service the industry, mainly sawmills.

Nordic Drives Group acquires Fabrika

Nordic Drives Group's acquisition of Danish Fabrika boosts our electric motor expertise and enhances energy-efficient solutions in Northern Europe.

Nordic Drives Group expands in Denmark

Nielsen & Rønne joins Nordic Drives Group, expanding our reach in Denmark with expertise in electric motor repairs, cranes, wind turbines and automation.