Custom-built gear motor brings Arla Mejeri back to full production

2025-10-21

A challenge in a crucial part of production

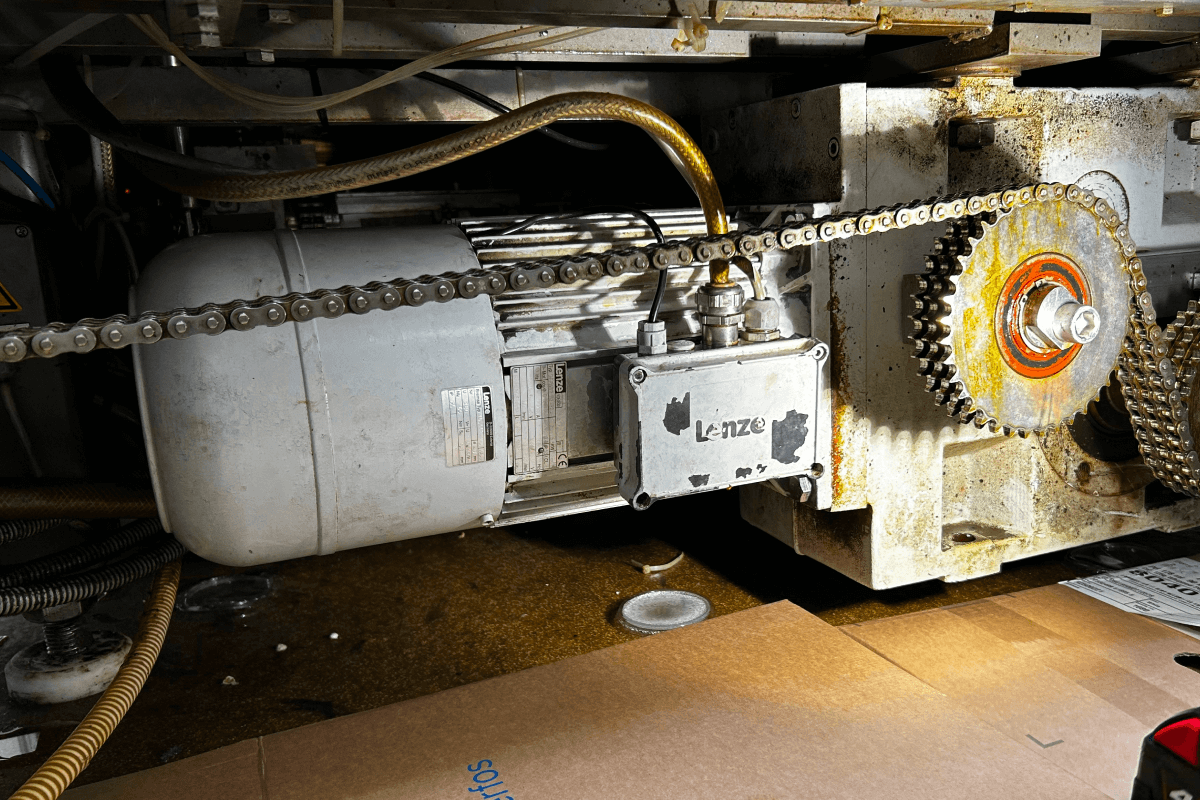

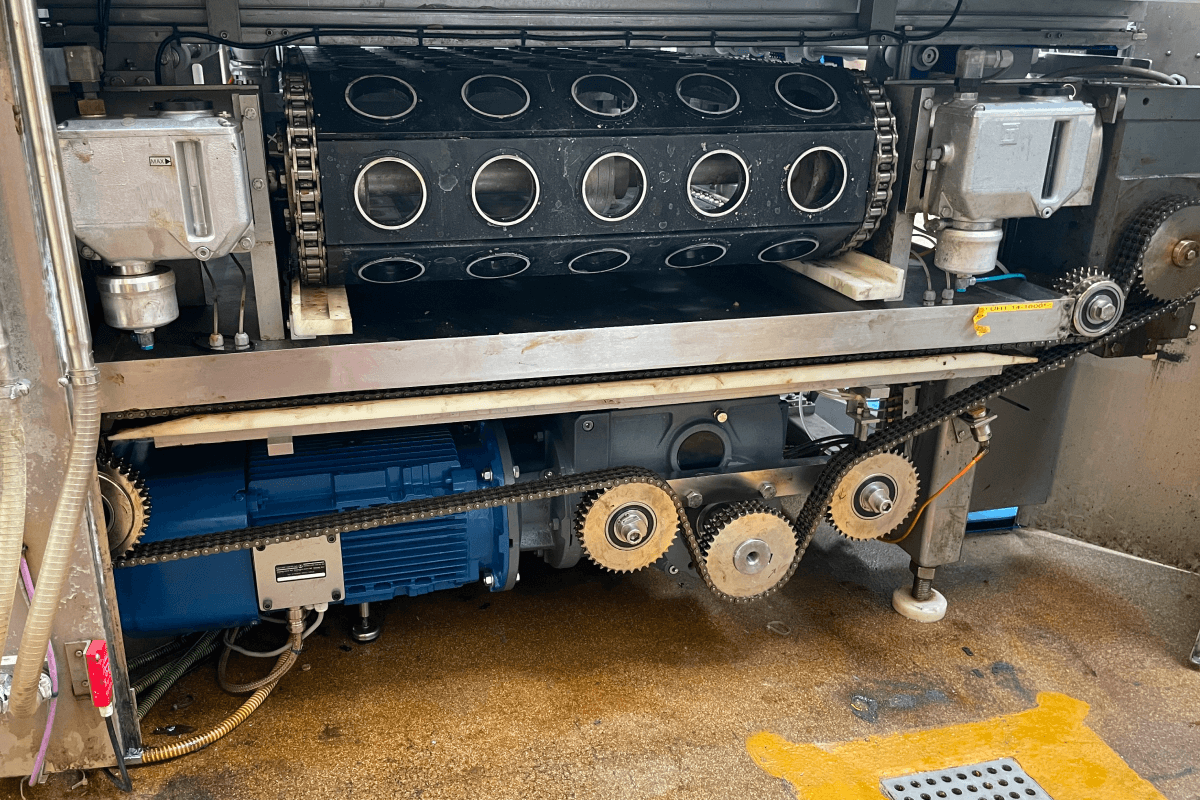

The defective gear motor was an outdated model for which no spare parts were available. Located in a key part of the process line, the breakdown had a major impact on production efficiency. As a long-term service partner to several Arla departments, our team at Aalestrup Elektro was trusted to find a reliable and compatible solution for the Holstebro facility.

Designing a custom-fit replacement

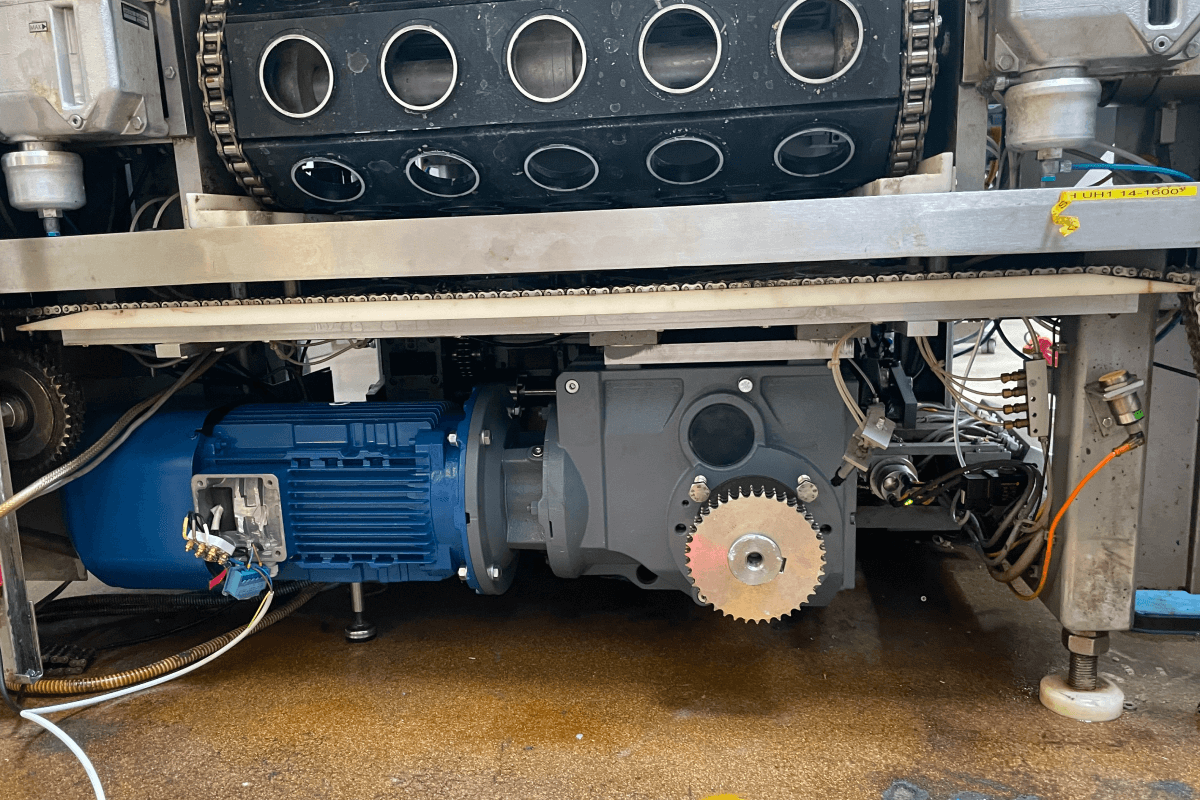

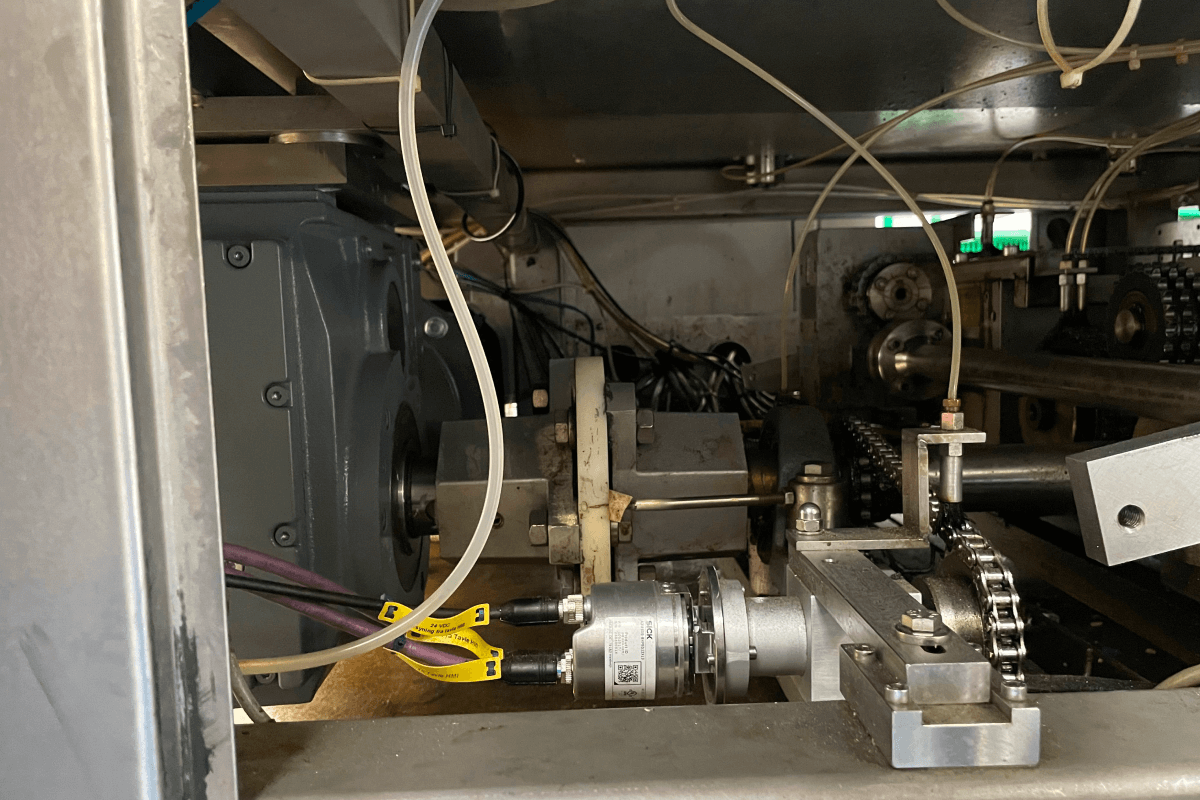

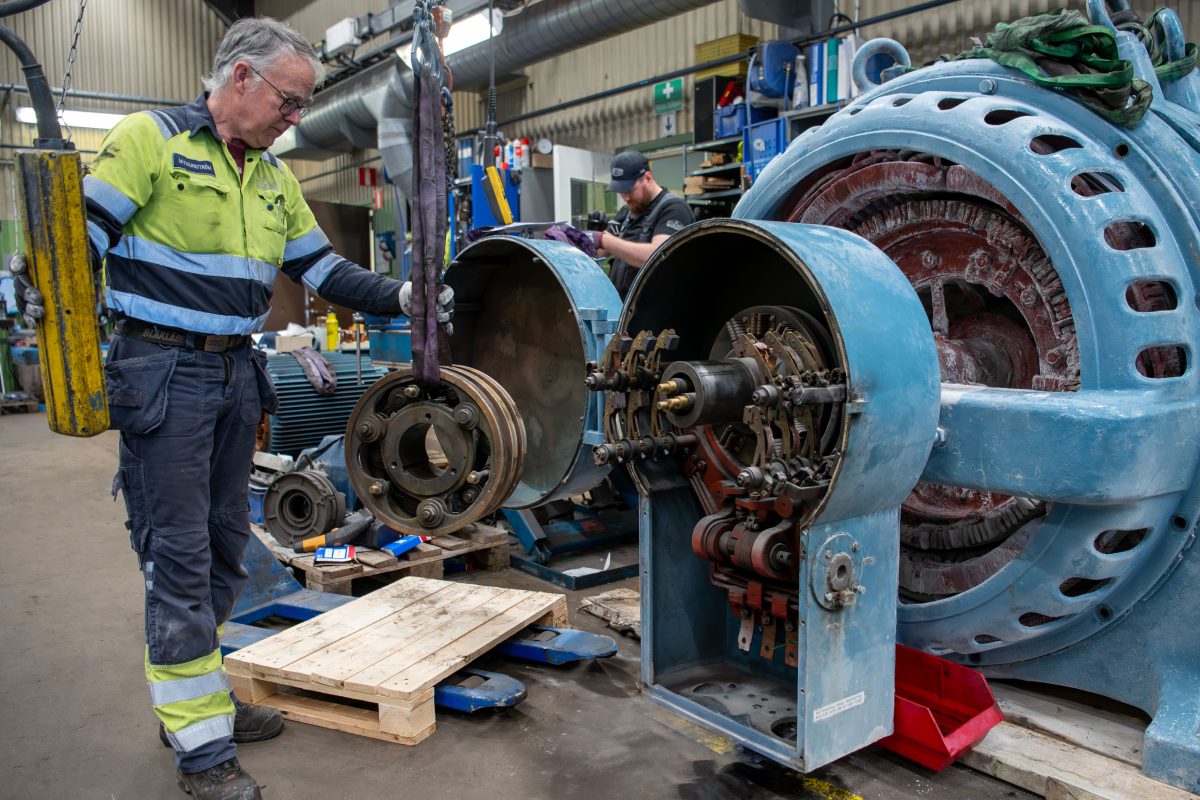

To meet the customer’s requirements, we identified a comparable gear motor and engineered several custom components, including an adapter plate, shaft, chain tensioner and terminal box cover. All parts were designed and manufactured in-house to ensure a 100% match with the original setup.

– The new gear had to fit perfectly and maintain exactly the same speed as before. Otherwise, the machine couldn’t operate correctly, says Simon Bøgelund, Project Manager at Aalestrup Elektro.

From issue to implementation

The project took approximately two to three months to complete, partly due to supplier challenges during the production of the custom parts. Once a new supplier was secured, the entire process could have been completed in about a month.

After installation and testing, Arla Mejeri’s cream cheese production was back in operation, with a satisfied customer and a smooth-running system.

For Aalestrup Elektro, projects like this are not uncommon.

– It happens regularly that we manufacture or adapt parts to fit our customers’ machines. When standard components aren’t enough, we make sure to engineer the right solution ourselves, Simon explains.

More news

Common signs of pump failure and how to prevent them

Krylbo Elektra shares key warning signs of pump failure – and how proactive service can help avoid downtime and costly repairs.

Aalestrup Elektro achieves ISO 9001 certification

Aalestrup Elektro strengthens its commitment to quality and safety with ISO 9001 certification, ensuring top-class service for explosion-protected equipment.

We’re strengthening our sales team with two new hires in Denmark

Nordic Drives Group strengthens its Danish sales team with two new hires: Dan Jensen and Jan Kristiansen. Both bring solid experience to support customers with reliable and tailored solutions.