Keeping industry running: Inside Jowic Elteknik’s 24/7 support

2025-12-16

With a central location, a large and flexible stock, and a support team available around the clock, Jowic Elteknik ensures fast access to critical components and expert assistance whenever it’s needed.

A centrally located stock built for fast deliveries

Jowic Elteknik’s warehouse is positioned in the middle of Sweden – a major advantage when serving customers from north to south. With roughly equal distance to their sister companies across Sweden, the team can ship parts quickly in all directions.

Locally, deliveries are made in a climate-smart way. The team uses an electric car to deliver material to nearby customers, combining speed with sustainability.

This combination of geography, flexibility and environmentally conscious transport creates a strong foundation for fast, reliable deliveries.

What sets their stock apart

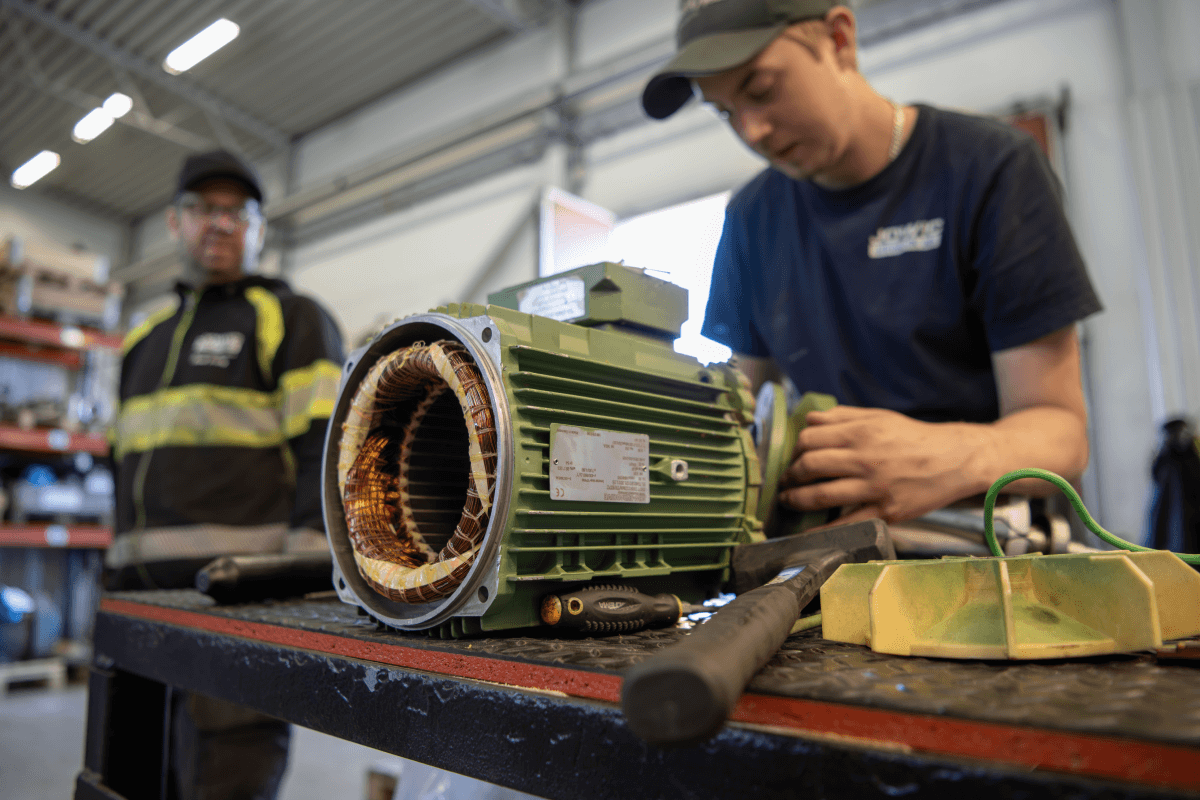

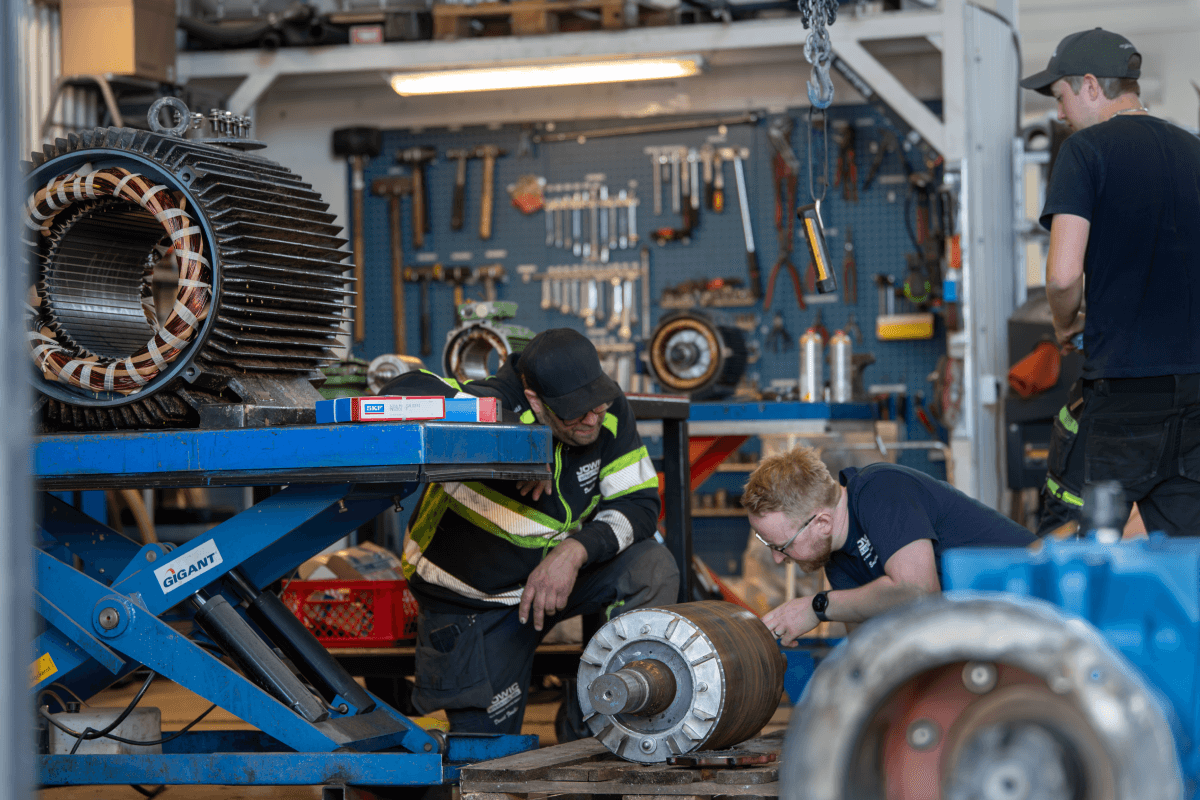

While many suppliers offer standard components, Jowic Elteknik focuses on adaptability. They stock a wide range of electric motors (0.25 kW–250 kW) and Variable Frequency Drives (3A–590A), including both standard and 500V/690V variants, but the real strength lies in how they configure equipment to match each customer’s needs.

– We adapt motors and VFDs with modular accessories, flanges and more, so customers get exactly what they need, Staffan Modig, Sales & Project Manager at Jowic Elteknik explains.

This approach makes their stock unique without revealing specific internal methods. Instead, customers experience it through fast turnarounds and tailored solutions.

Service and warranty partner for leading brands

Jowic Elteknik is an authorized service and warranty partner for both Danfoss and Emotron.

For customers, this means:

-

One point of contact

-

Faster troubleshooting

-

Access to certified repairs and support

-

Flexibility across a large installed base

It allows Jowic Elteknik to help the majority of customers in their region regardless of brand, which reduces downtime and simplifies daily operations.

Support that answers immediately and acts fast

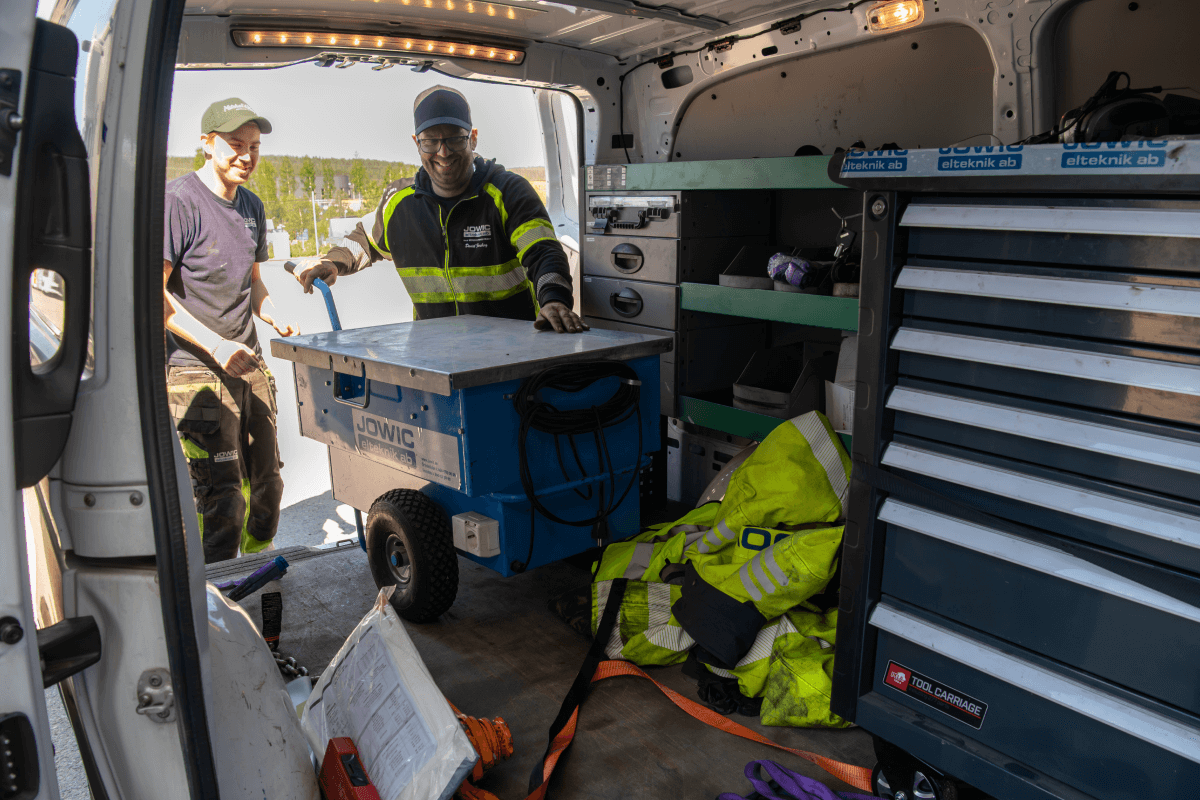

If a critical fault occurs, customers can expect instant response by phone. How fast a technician can be on-site depends on geography, but the ambition is clear: act immediately.

The 24/7 pickup service is a key part of that promise. Every member of the Jowic team is connected to the phone system, ensuring someone always answers. Customers can pick up materials themselves, or Jowic Elteknik can arrange taxi, courier or other transport.

Industries running continuous operations benefit the most – sawmills, steel, paper, and other heavy industries where downtime is extremely costly and flexibility is important.

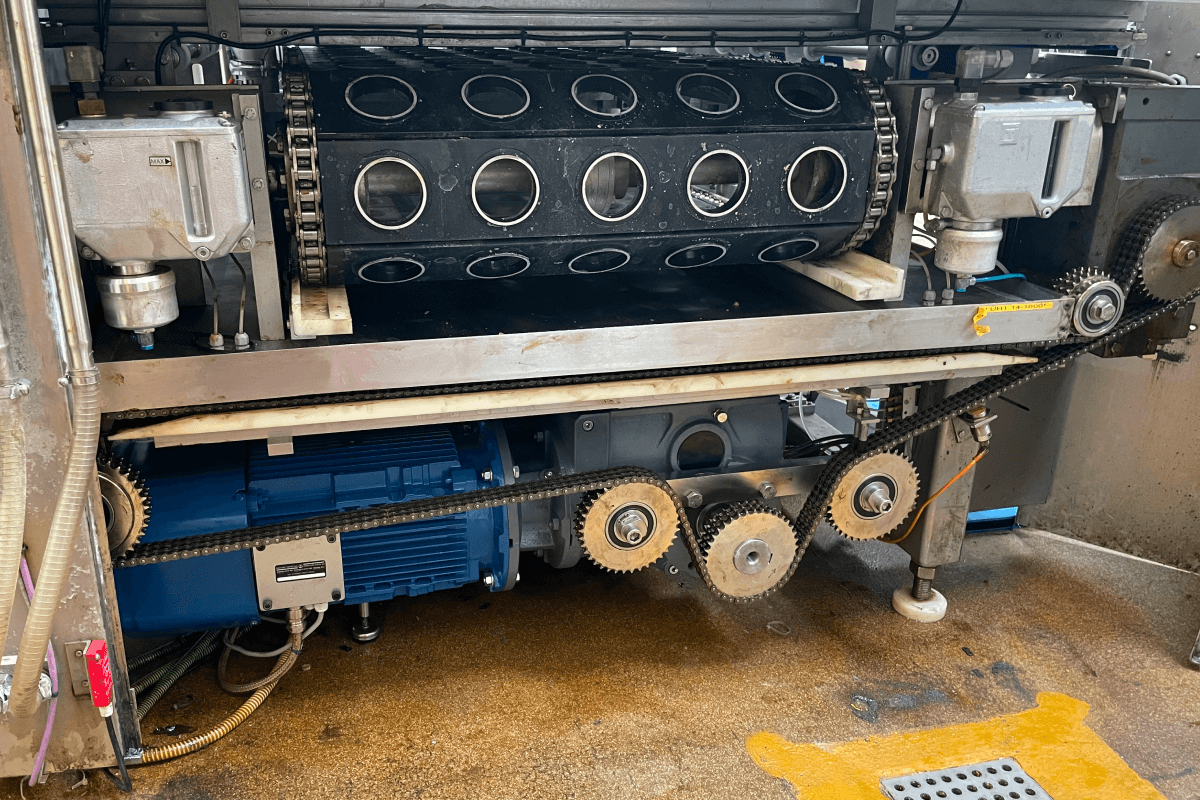

A real example: production stop at a sawmill

One sawmill located 450 km from Sundsvall experienced a production stop after a frequency drive failed at 15:00. Jowic Elteknik immediately dispatched two team members with a new 200 kW drive.

By 11:30 PM the same evening, the sawmill was back in operation.

These situations aren’t rare, they illustrate why Jowic’s combination of stocked parts, 24/7 access and experienced technical support makes a real difference for Swedish industry.

Ensuring uptime through expertise, availability and flexibility

With a smart stocking strategy, certified service partnerships, and round-the-clock access to critical components, they help customers keep their operations running safely and efficiently. Their combination of technical insight, logistical strength and fast response times continues to support Swedish industry – exactly when it matters most.

More news

We’re strengthening our sales team with two new hires in Denmark

Nordic Drives Group strengthens its Danish sales team with two new hires: Dan Jensen and Jan Kristiansen. Both bring solid experience to support customers with reliable and tailored solutions.

Aalestrup Elektro achieves ISO 9001 certification

Aalestrup Elektro strengthens its commitment to quality and safety with ISO 9001 certification, ensuring top-class service for explosion-protected equipment.

Custom-built gear motor brings Arla Mejeri back to full production

When a critical gear motor in Arla’s cream cheese production failed, Aalestrup Elektro designed and built a custom solution to get operations running again.