Why Variable Frequency Drives are key to energy-efficient and flexible operation

2025-11-17

What is a Variable Frequency Drive (VFD)?

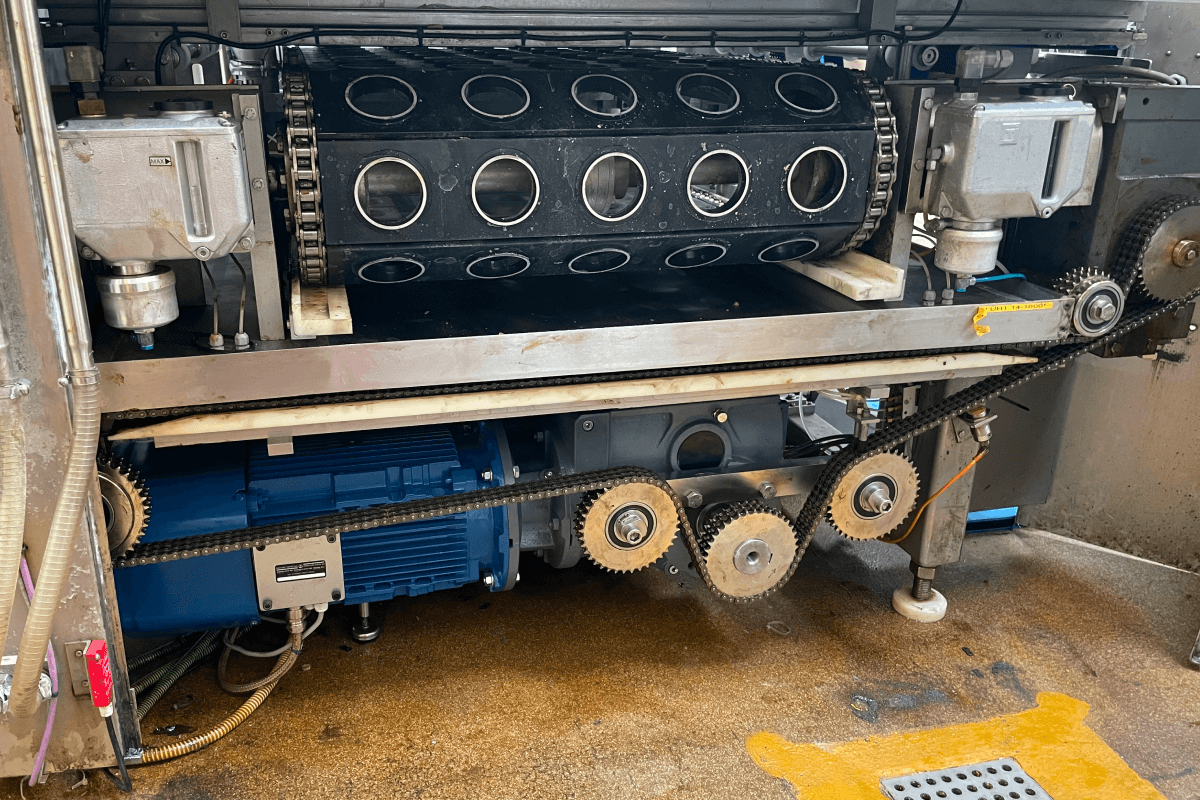

A Variable Frequency Drive controls how fast an electric motor runs by adjusting the frequency of the power supplied to it. In many industries, motors power pumps, fans, and conveyors, often running at full speed all the time when connected directly to the grid.

With a VFD, the motor speed can be matched to the actual demand. The result: lower energy use, reduced wear, and smoother operation.

4 key benefits of Variable Frequency Drives

Here are four concrete reasons to invest in a VFD:

-

Energy savings

By adjusting the motor speed to the actual process demand, energy consumption can be reduced significantly. In applications such as pumps and fans, studies show savings of up to 40% and sometimes even more. This means not only lower energy costs but also a smaller environmental footprint, especially in systems running continuously.

-

Improved process control

Precise control of speed and torque allows for optimized production in real time. This leads to smoother operation, consistent product quality, and reduced risk of process variations. In industries where accuracy and stability are critical, a VFD can make the difference between downtime and continuous production.

-

Extended lifespan and reduced maintenance

Soft starts and controlled acceleration reduce mechanical stress on shafts, bearings and gears. This protects critical components and can significantly extend the equipment’s lifetime. At the same time, smoother operation helps minimize unplanned downtime and lowers maintenance costs. A major advantage for facilities running around the clock.

-

Flexibility that lasts

Variable frequency drives make it easy to adjust motor control as conditions change, whether it’s new machinery, process adjustments, or higher energy-efficiency goals. This flexibility ensures long-term reliability and a future-proof system for industries that want to evolve without replacing their entire setup.

Choosing the right Variable Frequency Drive

Depending on whether you operate a conveyor, a pump or a fan, different types of Variable Frequency Drives are required. Each application has its own demands for speed, torque and control. You may also need specific features, depending on the system’s complexity and requirements for monitoring or energy efficiency.

Below are some key aspects to consider when choosing the right VFD for your operation:

-

Type of load and speed requirements

-

Compatibility with existing motor and drive system

-

Functions for monitoring, control and diagnostics

-

Energy requirements and sustainability goals

-

Access to documentation, spare parts and technical support

Over 90 years of experience in the industry

For us, frequency converters are more than just a component. They are a key part of how we help industries run their operations smarter, more efficiently, and more sustainably. With the right selection and integration, they become a tool for both cost savings and operational reliability.

With over 90 years of experience in electric motors and drive systems, we support our customers from consultation and design to delivery, installation, and maintenance. Together, we create performance that lasts – both technically and environmentally.

More news

Nordic Drives Group acquires Hirtshals El-motorservice ApS

Nordic Drives Group expands in Denmark by acquiring Hirtshals El-motorservice, boosting electromechanical services, marine generator & VPI capabilities.

Custom-built gear motor brings Arla Mejeri back to full production

When a critical gear motor in Arla’s cream cheese production failed, Aalestrup Elektro designed and built a custom solution to get operations running again.

We’re strengthening our sales team with two new hires in Denmark

Nordic Drives Group strengthens its Danish sales team with two new hires: Dan Jensen and Jan Kristiansen. Both bring solid experience to support customers with reliable and tailored solutions.